So I put on my ruby slippers clicked my heels three times and took the next tornado to Kansas City to finally do my mokume gane class. The course was hosted by the amazing Genevieve Flynn and taught by the equally amazing Eric Burris.

Genevieve is a jeweller with 30 years experience who teaches and hosts classes at her studio. She invites guest metalsmiths from the USA and overseas to come to Kansas City to teach workshops. A recent class was by Italian master repoussé artist Fabrizio Acquafresca from Florence who also teaches at the renowned Alchimia school. Genevieve’s studio was previously in downtown Kansas City and is now in the basement of her home.

Eric Burris studied mokume and laminated metals under Tedd McDonah (chair of this year’s SNAG conference) at Arizona State University. Eric makes contemporary pieces that combine wood and mokume gane. His works often reference geographical locations by incorporating small sections of maps.

With Eric we learned how to do torch fired mokume gane billets in a fire brick kiln and make seamless twisted mokume gane rings. When I made mokume gane before at Design Centre Enmore I used the electric kilns, which worked great, but not having a kiln, I haven’t been able to make any since. The great thing about Eric’s class was that he showed us how it can be done in a small home studio without a huge amount of expensive equipment.

For those who don’t know, mokume gane is a traditional Japanese metalworking technique dating back to the 1650s when it was invented by master Denbei Shoami to make decorative samurai sword fittings. Layers of different metals, usually copper and silver alloys are bonded together in a stack. The stack or billet is then forged, flattened and carved to make patterned sheet metal that looks a bit like wood grain. Mokume gane in Japanese means ‘eye of the wood grain’.

These are the pieces I made in 2010 while at Enmore.

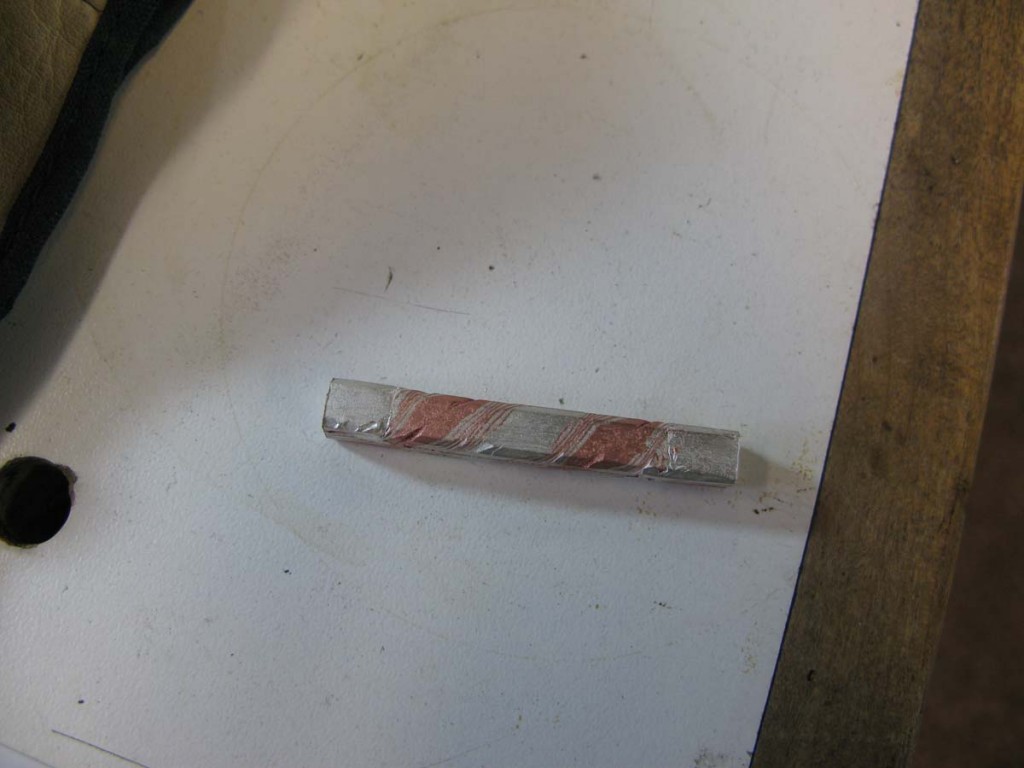

This is what my sheets of mokume looked like after patterning before I made the rings.

With Eric we made 12 layer billets of alternating copper and silver, each sheet was half by three quarters of an inch or 12 x 19mm.

I found the workshop extremely useful and informative. Eric is a great teacher and explained all the steps very clearly. I think the fact that I have already made mokume, meant that I got even more out of it, as I had a really good understanding of what was going on. The size of the class was perfect, there were only 5 or 6 of us, so Eric was able to give each student personal attention. The length of the class, 3 days, was also really good as we were each able to get our rings up to a stage where we could easily finish them at home.

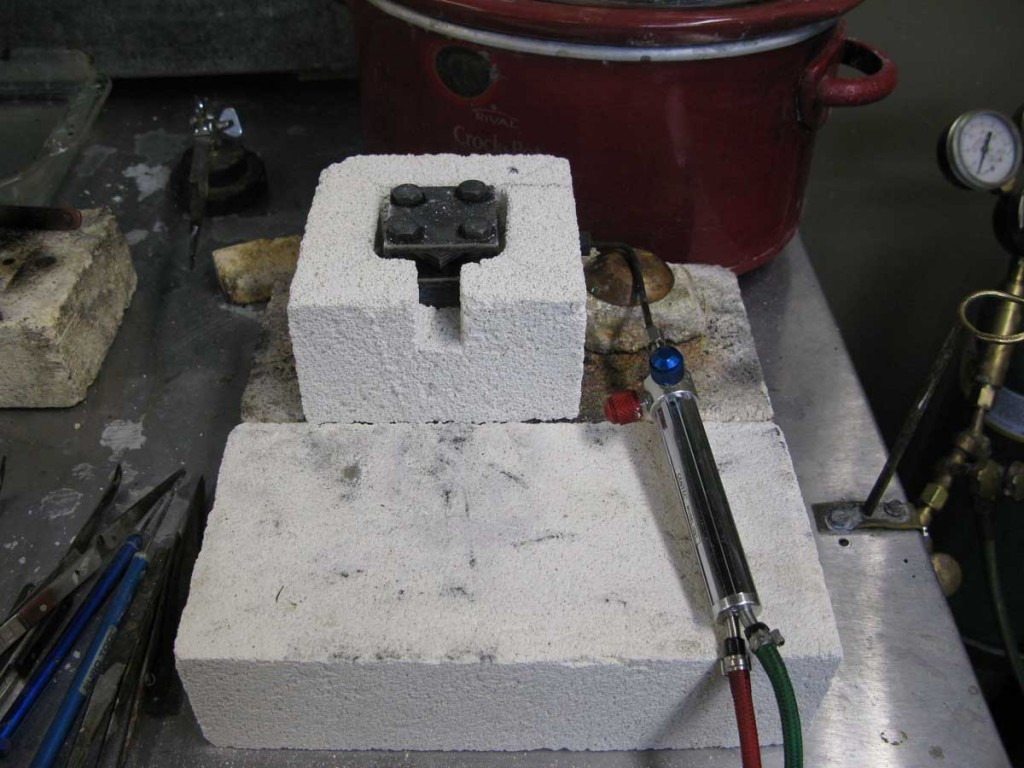

The billets were fired with a Smith Little Torch with a rosebud tip running oxy-acetylene.

Anyway, to get down to nuts and bolts – making mokume is quite involved so I won’t go into all the steps in detail or I’ll be here all week. This is what we did in brief:

- Make fire brick kiln: cut a brick in half and hollow out cavities on both sides using a rasp bit on a drill press or by hand with a scraper.

- Cut sheets: cut all edges with a saw or file off the bur from the guillotine.

- Scrub sheets with Scotchbrite and degreaser, wear gloves.

- Stack sheets: hold in a vice clamp, then wrap the edges with masking tape.

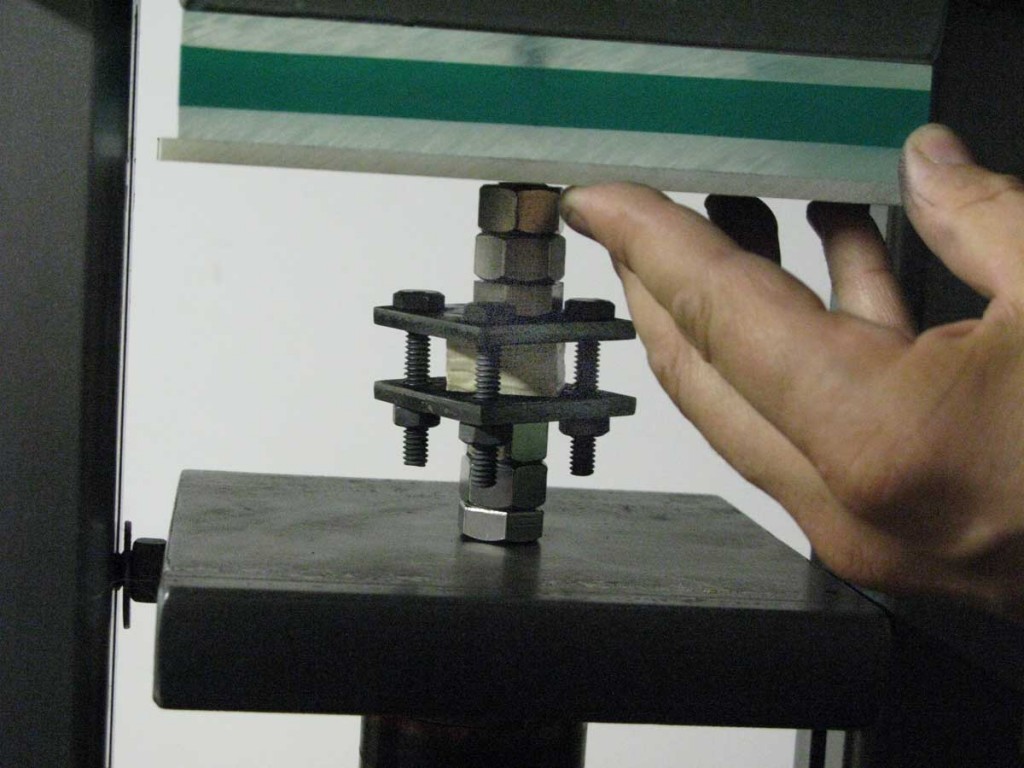

- Fit the stack into torque plates then compress in either a hydraulic press or a vice & tighten bolts.

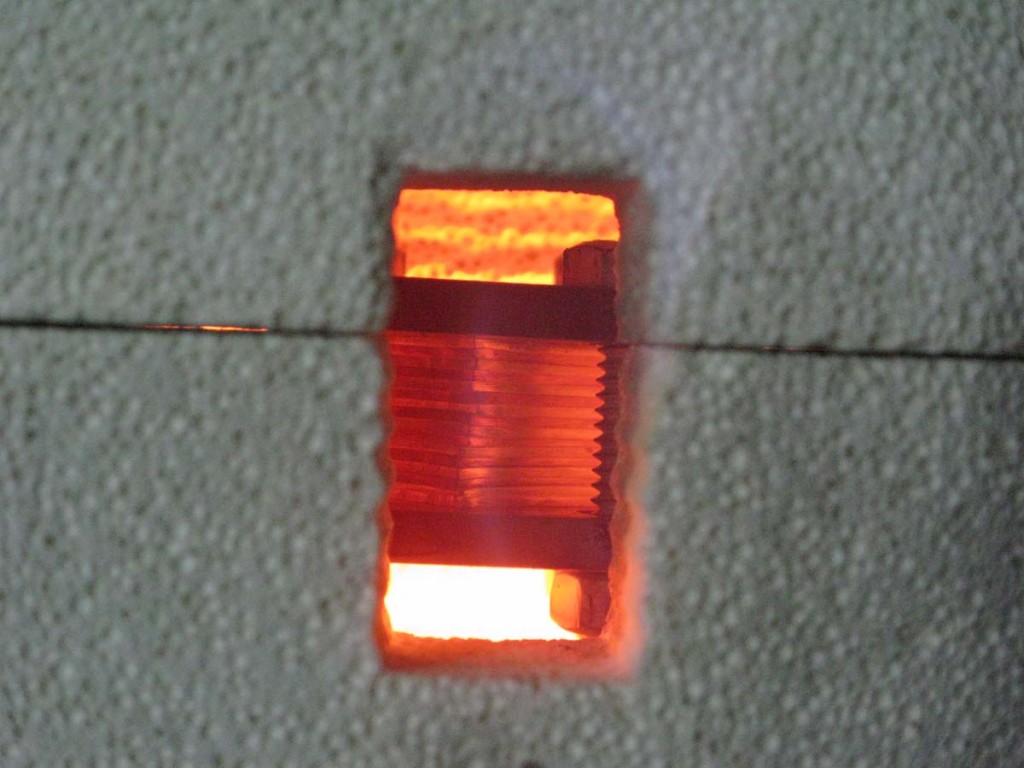

- Fire the billet in the kiln using an oxy acetylene torch, watch through the window for the layers to sweat.

- Remove promptly from kiln & hammer the plates while hot.

- Remove the billet from the plates & let cool.

- Grind off oxidised edges of the billet with an angle grinder.

- Forge the billet to half its thickness.

- Roll in a rolling mill to quarter inch thickness.

- Cut off a quarter inch strip with a hacksaw.

- Anneal and twist the strip with vice grips and a vice while hot.

- Hammer the twist square on an anvil.

- Roll to quarter inch thickness/diameter.

- Drill holes at either end and cut slot.

- Open the slot with a screw driver and hammer round on a mandrel.

- File and finish, solder inner liner band.

- Play with Genevieve’s gorgeous long-haired cats Atticus and Milly.

Here’s a pic of all of us who did the class with Eric.

Deb Weld, Jennifer Finley, Julie Van Hoecke, Whitney Wilson, Eric Burris, & me.

Here’s an attractive pic of me forging my billet which Genevieve took.